NEW: RUD TXP-Texolution-Point

The textile lifting point for the protection of surfaces and loads.

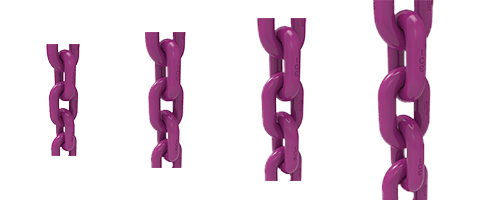

Innovative RUD lifting means, lifting points and lashing equipment have been setting benchmarks for the safe movement of loads for decades. More than 700 tested lifting and lashing points up to 250 tonnes WLL – as weldable or boltable versions – reduce handling costs and increase working safety. With a variety of 370 chain components in Grade 8, 10 and 12 in nominal size 4 - 28 mm available, all lifting and lashing jobs can be solved safely.

RUD is the first manufacturer of round steel chains with the highest Grade approval (D1-12) from the employers’ liability insurance association. Identification and inspection are made significantly easier thanks to the standard equipment and marking with RFID transponders. And the in-house developed hardware and software of the RUD BLUE-ID SYSTEM make processing and management more efficient and faster.

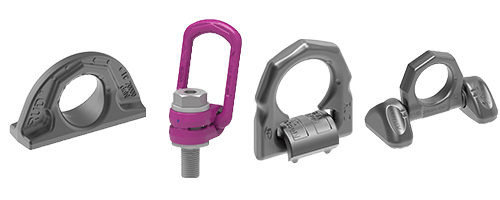

RUD lifting points and slings stand for reliability, health & safety at work and quality “Made in Germany”. Thanks to the comprehensive range of lifting points and slings available, loads weighing 100 kg to 250 tonnes can be lifted, moved and transported safely. 700 different tested RUD lifting point variants in welded and forged versions are available for all lifting technology applications.

How do I connect the lifting means with the load or the loaded goods?

product details

What has to be taken into account when selecting chains (length, material, diameter etc.)?

product details

What must be taken into account when choosing the right lifting points?

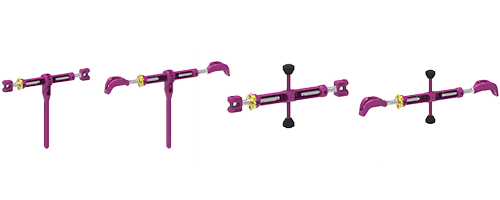

product detailsDuring the transportation of machines or components, high forces often act on the load. For safe transportation, it is important to apply the necessary retaining forces reliably in order to keep the load on the load bed.

Lashing points connect the load bed with the lashing chain. Lashing points from RUD are available both in weldable and in boltable versions.

product details

Shortening elements make manual fast-shortening possible for the subsequent ideal adjustment of the tensioning elements.

product details

Tensioning elements make fast and easy pre-tensioning possible. In addition, RUD tensioning elements have a practical mechanical locking device and an anti-theft device.

product details

Identification tags from RUD contain information about the respective lashing chain (reliable lashing force, pre-tension force etc.). In addition, it can be used to check the main set-down criteria of the chain (Gauge function).

product details

The ICE Lashing Chain replaces grade 8 of the next largest nominal thickness and has an up to 60% higher breaking load (significant weight savings, improved ergonomics, faster attachment and increased safety through improved material properties).

product details

Lashing points connect the loading area with the lashing chain. Lashing points from RUD are available in both weldable and boltable versions.

product details

Chain slings configuration has never been easier: Put together the perfect lifting means online in just a few steps. Simple, fast and safe. See the finished suspension in 3D, automatically create a parts list, share the result with your RUD experts or your dealer and send an enquiry directly. In addition: Profit from valuable insights.

Register now and benefit free of charge!